Your sales person will quote you PCB manufacturing cost, PCB assembly cost , and components parts cost, We will list all detail in quotation.

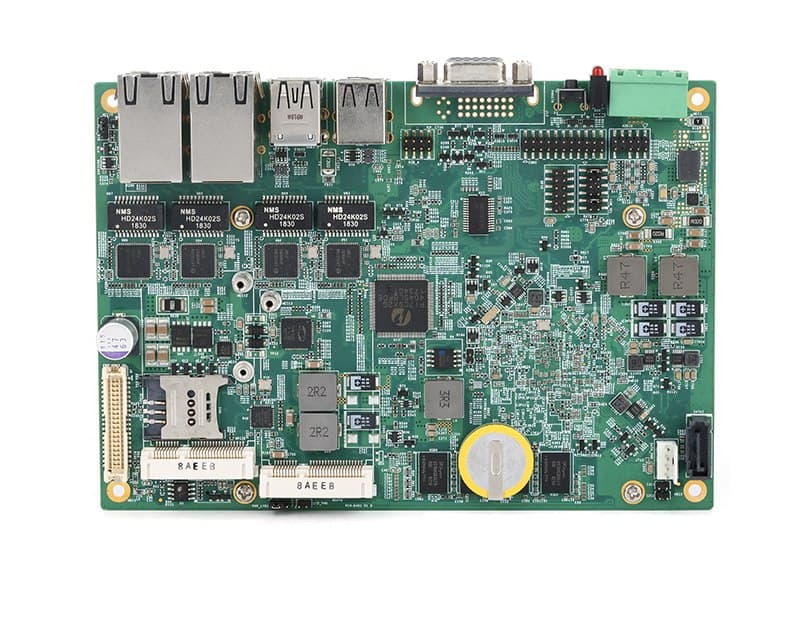

One-Stop PCB Assembly Service

Reliable full turnkey PCB service solution for prototype quantities as well as small-volume to mid-volume production runs, and a one stop PCB manufacturing and assembly Manufacturer.

SMT PCB Assembly Services

Dedicated To High Complex PCB: High DK, Blind cross buried, Rigid-Flex, extreme copper PCB …

Electronic Manufacturing

PCB Assembly Services

RAYMING is China PCB assembly manufacturer, who offers complete PCB assembly services in Shenzhen, RAYMING’s capable of providing turn-key and partial turn-key printed circuit board assembly services.

For full turn-key, we take care of the entire process, including manufacturing of Printed Circuit Boards, procurement of components (100% original), PCBA Testing, continuous monitoring of quality and final assembly.

Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by RAYMING.

PCB Assembly Solutions

PCB Fabrication

Up to 100 Layer PCB Manufacturing Service

PCB Stencil

Laser Cut SMT Stencils with your PCBs

Parts Sourcing

Full/Partial Electronic Components Bom List Sourcing

PCB Assembly

A Seamless Process from PCB to Assembly

IC Programming

Online / Offline programming Services

PCBA Testing

ICT FCT AOI X-RAY Fatigue Test, Aging Test

Prototype PCB Assembly

Small and medium runs with fast lead-times and no minimum quantity requirements

Turnkey Assembly

Full and partial Turn-key PCB Assembly Services on both rigid PCB Assembly and flex PCB assembly.

Flex PCB assembly

Same assembly process with some special operations on different technical requirement for Flexible assembly.

PCB Assembly Projects

Industries we served

MEDICAL INSTRUMENTATION

TEST & MEASUREMENT

LED LIGHTING

AUTOMOTIVE

CONSUMER ELECTRONICS

MARINE

INDUSTRIAL EQUIPMENT

COMMUNICATION NETWORKS

SOLVE YOUR DOUBTS

PCB Assembly FAQs

Send PCB files and Bom list to sales@raypcb.com with quantity and requirement, We will assign a sales person for one-on-one service, She will quote you in 24hours and follow rest.

Yes, We do, This called partial Turn-key. You can supply some parts, and we source the rest of the parts on your behalf. We will ask for your approval for anything that is not sure at our side. In case parts crossing or substitution is needed, we will again ask for your final approval.

We offer SMT, combined surface mount, chip on board, multi-layer quick turn prototypes and more based on custom specification and requirements!

Well, the cost depends on your requirements including design, complexity, number of layers, etc.

We cater our services in electronics, automotive, telecommunication, medical, renewable energy, and several other industries.

We need Gerber files, Centroid data and BOM for your PCBA orders. As have already placed your PCB order with us, actually you only need to send the latter two if your PCB Gerber files have included the layers of silkscreen, copper track and solder paste. If your PCB Gerber files are missing any of the above-mentioned three layers, please resend them, as this is the minimum request for PCBA. For the best possible result, please also send assembly drawings, instructions and photos to us to avoid any ambiguous and even mistaken placement of parts, though these are not required by most of the assemblers.

No, We donot, You can start from 1 pcs PCBA.

Of course, yes. We provide complete box-build services from printed circuit board design, manufacturing, assembly to end product prototyping PCB!

Our value-added services include electro-mechanical assembly, cable and wire harness assembly, box builds, panel assembly, specialized PCB rework, BGA assembly, RoHS compliant PCBs, conformal coating, potting, encapsulation, testing, and more.

Centroid is the special file for assembly used for quickly programming the assembly machines. This is also known as aka Insertion, Pick-N-Place, or XY Data. Some of the CAD tools will automatically generate this file and some not, but you may need to modify the file and then generate the Centroid file. The Centroid file describes the position and orientation of all the surface mount parts, which includes the reference designator, X and Y position, rotation and side of Board (Top or Bottom). Only surface mounting parts are listed in the Centroid.

SMT Engineering & Technical

- What is Turnkey PCB Assembly Service ?

- How Do You Assemble a flex PCB?

- Who is the Best Low Volume PCB Manufacturer?

- How Do You Make a PCB Panel ?

- What Is A Box Build Assembly In PCB Electronics ?

- Top 15 Prototype PCB Assembly Manufacturers

- PCBA Test

- What is PCB Stencil ?

- What is IC programming and IC Programmer ?

- Electronic Component Procurement and circuit board components Sourcing Solutions

- Basic Thing You Should Know About PCB Assembly Process

- What is the difference between wave soldering and reflow soldering?

- Step-by-step BGA manufacturing process

- What is the Difference Between SMD Soldering and DIP Soldering?

- What is Conformal Coating on PCBs?

- What is Selective Solder

- The Essential Steps to Testing a PCB

- Rigid-flex PCB assembly – The Basics and How it Works

- How to Solder LGA and BGA Packages: What is LGA BGA?

- How do you rework a BGA?