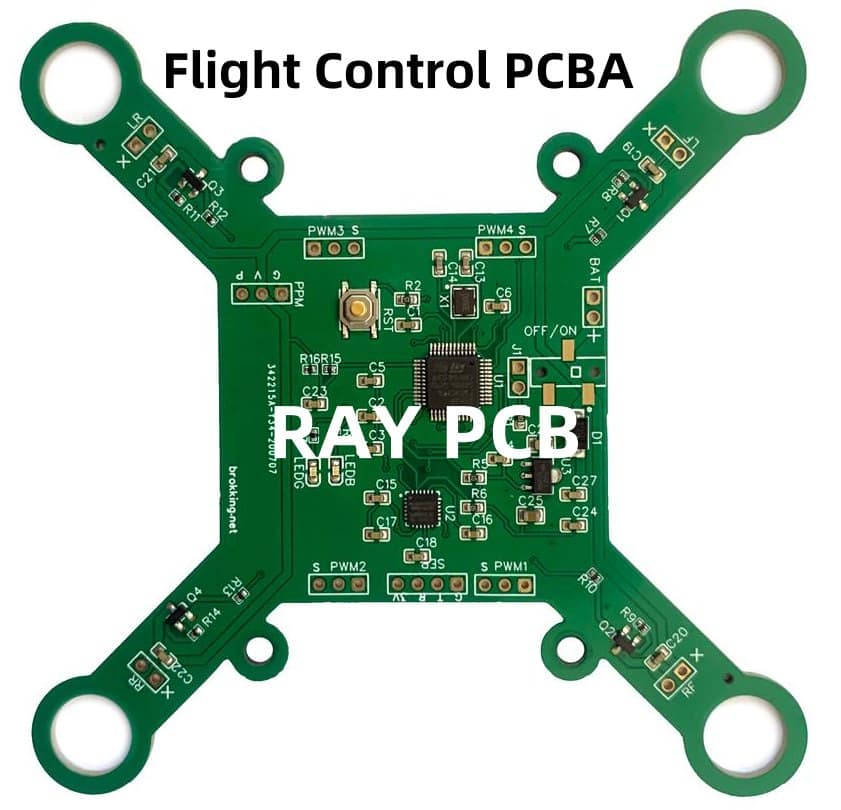

In the dynamic world of aerospace engineering, the design and development of reliable and efficient flight control systems are paramount to ensuring safe and precise aircraft operation. These complex systems require a harmonious integration of hardware, software, and electronics components, making the hardware and Printed Circuit Board (PCB) design process a critical aspect. KiCAD, an open-source suite of tools for electronic design automation (EDA), has emerged as a powerful solution for designing flight control systems, offering a comprehensive set of features for schematic capture, PCB layout, and simulation.

This article explores the intricacies of flight control system design, focusing on the hardware and PCB aspects using KiCAD. We will delve into the essential components, design considerations, and best practices that engineers should understand when developing these intricate systems. Additionally, we will highlight the advantages of using KiCAD and its various tools for streamlining the design process.

Understanding Flight Control Systems

Flight control systems are responsible for maintaining the stability, maneuverability, and desired flight path of an aircraft. These systems typically consist of three main components:

- Sensors: Sensors collect data related to the aircraft’s attitude, altitude, airspeed, and other relevant parameters. Common sensors used in flight control systems include gyroscopes, accelerometers, pitot tubes, and GPS receivers.

- Control Computers: Control computers, often microcontrollers or embedded systems, process the sensor data and execute algorithms to determine the appropriate control actions.

- Actuators: Actuators, such as servos or hydraulic systems, translate the control commands into physical movements of the aircraft’s control surfaces (e.g., ailerons, elevators, and rudder).

The hardware and PCB design play a crucial role in integrating these components and ensuring reliable and efficient operation of the flight control system.

Hardware Design Considerations

When designing the hardware for a flight control system, several factors must be taken into account:

1. Sensor Integration

Proper sensor integration is vital for accurate data acquisition. Engineers must consider factors such as sensor placement, shielding, and signal conditioning to minimize noise and interference. Additionally, the sensor interfaces (e.g., I2C, SPI, or analog) must be compatible with the control computer.

2. Microcontroller Selection

The microcontroller or embedded system serves as the brain of the flight control system. Selection criteria include computational power, memory capacity, peripheral interfaces, and real-time performance. Common microcontrollers used in flight control systems include ARM Cortex-M series and Atmel AVR microcontrollers.

3. Power Management

Efficient power management is essential for flight control systems, especially in battery-powered aircraft. Designers must consider power consumption, voltage regulation, and power distribution to ensure reliable operation and extend battery life.

4. Environmental Considerations

Flight control systems must operate in harsh environments, including varying temperatures, vibrations, and electromagnetic interference (EMI). Hardware design should incorporate measures such as thermal management, shock and vibration isolation, and EMI shielding to ensure reliable operation.

5. Redundancy and Fail-Safe Mechanisms

Safety is a critical aspect of flight control systems. Redundant components, watchdog timers, and fail-safe mechanisms should be implemented to prevent catastrophic failures and maintain control in the event of component malfunctions.

PCB Design Using KiCAD

KiCAD is a powerful open-source EDA suite that provides a comprehensive set of tools for PCB design, including schematic capture, PCB layout, and simulation. Here’s how KiCAD can be leveraged for flight control system PCB design:

1. Schematic Capture

KiCAD’s Eeschema component allows for the creation of schematics by placing components and interconnecting them with wires and buses. Engineers can create hierarchical schematics, assign footprints to components, and perform electrical rule checks (ERCs) to ensure design integrity.

2. PCB Layout

Pcbnew, KiCAD’s PCB layout tool, enables engineers to transform schematics into physical PCB layouts. Features such as automatic track routing, differential pair routing, and interactive length tuning simplify the layout process. Additionally, KiCAD supports various design rules and constraints to ensure manufacturability.

3. Libraries and Component Management

KiCAD offers extensive component libraries, including standard components and user-defined libraries. Engineers can create custom footprints and symbols for specialized components, ensuring accurate representation and integration into the design.

4. Simulation and Verification

KiCAD’s simulation capabilities, including SPICE integration and signal integrity analysis, allow for pre-manufacturing verification of the design. Engineers can simulate and analyze the behavior of analog and digital circuits, ensuring proper functionality and identifying potential issues before prototyping.

5. 3D Visualization and STEP Integration

KiCAD’s 3D viewer and STEP integration enable engineers to visualize the PCB design in a 3D environment, facilitating mechanical integration and ensuring proper fit within the aircraft’s structure.

6. Manufacturing Output

KiCAD supports various manufacturing output formats, including Gerber files, drill files, and pick-and-place files. This streamlines the transition from design to manufacturing, enabling efficient collaboration with PCB fabrication and assembly services.

Design Workflow and Best Practices

When designing flight control systems using KiCAD, it is essential to follow a structured workflow and adhere to best practices to ensure a successful outcome:

1. Requirements Gathering and Planning

Begin by clearly defining the system requirements, including performance specifications, environmental conditions, and safety standards. Develop a comprehensive design plan that outlines the hardware architecture, component selection, and design constraints.

2. Schematic Capture and Component Selection

Create detailed schematics in KiCAD’s Eeschema, carefully selecting components that meet the design requirements. Ensure proper component footprint assignment and perform electrical rule checks to validate the schematic.

3. PCB Layout and Routing

Translate the schematic into a physical PCB layout using Pcbnew. Follow best practices for component placement, routing, and signal integrity. Utilize KiCAD’s design rule checks and constraint management tools to ensure manufacturability.

4. Simulation and Verification

Leverage KiCAD’s simulation capabilities to verify the design before prototyping. Perform circuit simulations, signal integrity analysis, and electromagnetic compatibility (EMC) analysis to identify and address potential issues.

5. Prototyping and Testing

Once the design is verified through simulation, create prototypes for thorough testing and validation. Test the flight control system in relevant environmental conditions and perform functional tests to ensure compliance with system requirements.

6. Iteration and Refinement

Based on the test results, iterate and refine the design as necessary. Update the schematics, PCB layout, and simulations to incorporate improvements and address any identified issues.

7. Manufacturing and Integration

When the design is finalized, generate the necessary manufacturing output files (e.g., Gerber files, drill files) and engage with PCB fabrication and assembly services. Ensure proper integration of the PCB into the aircraft’s structure and system.

8. Documentation and Version Control

Maintain comprehensive documentation throughout the design process, including design specifications, test reports, and assembly instructions. Implement version control practices to track changes and facilitate collaboration within the engineering team.

Advantages of Using KiCAD for Flight Control System Design

Choosing KiCAD for flight control system design offers several advantages:

- Open-Source and Cost-Effective: As an open-source EDA suite, KiCAD provides a cost-effective solution for hardware and PCB design, making it accessible to organizations of various sizes and budgets.

- Cross-Platform Compatibility: KiCAD is available for multiple operating systems, including Windows, macOS, and Linux, ensuring flexibility and compatibility across different development environments.

- Community Support and Resources: KiCAD has a large and active community of users and developers, providing access to extensive documentation, tutorials, and support forums, facilitating knowledge sharing and problem-solving.

- Customizability and Extensibility: KiCAD’s modular architecture and scripting capabilities allow for customization and integration with third-party tools, enabling engineers to tailor the design environment to their specific needs.

- Comprehensive Feature Set: KiCAD offers a wide range of features, including schematic capture, PCB layout, simulation, and manufacturing output, providing a complete solution for flight control system design.

- Interoperability and Data Exchange: KiCAD supports various file formats for data exchange, enabling seamless collaboration with other EDA tools and integration into existing design workflows.