Introduction

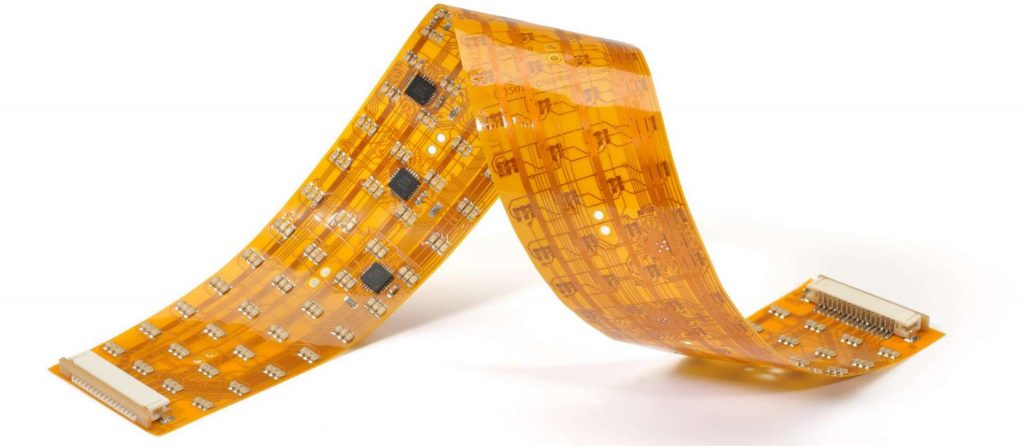

Flexible printed circuit boards (flex PCBs) provide unique capabilities for bending and conforming electronic circuits to fit challenging mechanical packages. However, the advanced manufacturing process comes at a cost premium versus rigid PCBs.

When designing a product utilizing flex PCBs, accurately estimating cost early is crucial for budgeting new programs. This guide will examine the key variables that drive cost and provide guidance on estimating.

By reading this, engineers can avoid sticker shock and make informed design decisions when planning flex PCB implementations. We’ll explore factors like layers, size, materials, tolerances, and more that ultimately determine total flex PCB cost.

Layer Count

The number of conductive copper layers has a major influence on flex PCB pricing. Each additional layer adds cost.

Typical Flex Layer Ranges

- Single Sided – 1 layer

- Double Sided – 2 layers

- Multilayer – 3 to 12+ layers

In general, expect each additional layer to increase cost by 25-50% or more over the preceding layer count. The exponential cost increase is due to complex lamination processes required to create multilayer boards.

Higher layer counts allow more complex routing, but weigh the benefits vs. cost impact.

Board Size

Larger flex PCB sizes cost more due to raw materials and panel utilization factors.

Typical Size Ranges

- Small – Under 4 in2

- Medium – 4 in2 to 16 in2

- Large – Over 16 in2

Expect roughly 20-30% higher cost for each doubling of board dimensions. Carefully consider optimal board size vs. design constraints.

Nonstandard shapes can also drive cost due to panelization inefficiencies. Square or rectangular boards are most economical.

Thickness

Flex circuit thickness is specified as the copper thickness in ounces. Common thicknesses are:

- 0.5 oz – For lightweight, high flexibility

- 1 oz – Typical for many applications

- 2 oz – Thicker copper for high current

- 3 oz – Limited bend radius applications

Thicker copper will increase fabrication cost, but may be necessary for electrical or mechanical performance.

Flexible Dielectrics

The base material choice affects cost due to material variations in price, processing differences, and availability.

Common Flex Dielectrics

- Polyimide – Most popular, high performance, mid price

- Polyester – Lower cost but lower temperature

- PEN – High temperature thermoplastic

- LCP – Extremely high temperature and chemical resistance

- PEEK – Ideal for impedance control

Consider compatibility with operating temperature, chemical exposure, impedance needs, and other mechanical requirements.

Dielectric Thickness

Flex PCB dielectrics are available in different standard thicknesses:

- Thin – Around 0.001 in (25 μm)

- Standard – 0.002 to 0.005 in (50 to 125 μm)

- Thick – Above 0.005 in (>125 μm)

Thinner dielectrics enable high flexibility in flex circuits. However, standard thicknesses offer a good balance of cost, availability, and mechanical strength.

Stiffener Layers

For rigidity or to enable connectors, stiffener materials can be added:

Common Stiffener Materials

- FR4 – Fiberglass, cost effective, moderately rigid

- Polyimide – More expensive, very high temperature

- Aluminum – Flat wire or thin plates, highest rigidity

Stiffeners increase fabrication complexity and material cost. Use judiciously or avoid completely if possible.

Adhesives

Flex-to-flex bonding requires adhesive layers. Common choices:

- Acrylic – Basic electrical and temperature performance

- Epoxy – Enhanced resistance for high reliability

More advanced adhesives can provide thermal conductivity, high temperature tolerance, and low moisture absorption. Avoid addition of adhesive if not required.

Coverlay Layers

Coverlay encapsulates and protects external flex layers. Typical coverlay materials:

- Liquid photoimageable (LPI) solder mask – Most common

- Vacuum laminated polyimide – For high durability and abrasion resistance

Coverlay is frequently required for reliability. However, customize cutouts to minimize usage since it adds cost.

Shielding

For EMI shielding, conductive layers can be added:

- Anisotropic conductive film (ACF) – Provides moderate EMI shielding

- Copper or aluminum foil shields – Higher attenuation for strict shielding needs

- Molded metallic shells – Integrated metal-plastic enclosures

Only utilize shielding when necessary due to substantial fabrication and material costs.

Text and Graphics

Any custom graphics like logos, text, and component outlines add cost. Minimize usage to only essential nomenclature and markings.

Solder Mask

Solder mask is standard on exterior layers to prevent solder bridges. Additional considerations that affect cost:

- Different color masks possible but may incur surcharges

- Non-standard openings may require additional tooling charges

- Tight registration and solder dams increase difficulty

Minimize special solder mask needs when possible by designing within capabilities.

Surface Finishes

ENIG (electroless nickel immersion gold) is the standard surface finish for excellent solderability and bond pad protection.

Optional finishes:

- Immersion silver – Lower cost but higher contact resistance

- Immersion tin – Cheaper but prone to oxidization

- Gold over nickel – Maximum wear resistance for connectors/contacts

- Conductive anodization – Aluminum boards only

Compare tradeoffs of surface finish performance vs. cost impact.

Tolerances

Standard flex PCB fabrication allows a reasonable degree of tolerance on features. When specifying boards:

- Avoid calling out extremely tight tolerances like less than ±0.003 in unless absolutely necessary

- Relax hole diameter and cutout tolerances if possible

- Allow for +/- 0.5 to 1 mm component placement latitude

Holding super tight tolerances increases fabrication tooling complexity and scrap rates, which rapidly increases cost.

Small Quantities

Prototypes and small batch orders won’t see the full economy of scale savings. Expect higher cost impact for:

- Prototypes less than 10-25 units

- Production volumes under 100-500 units

Amortize NRE and tooling costs over small runs. Move to larger production runs to optimize cost.

Quick Turnaround

Expedited delivery of flex PCB prototypes in under 5-10 days incurs surcharges and may limit manufacturing options. Allow longer lead time for cost savings when possible.

Special Processing

Any non-standard flex PCB processes will add cost:

- Via filling

- Controlled depth drilling

- Laser trimming of components

- Thick copper layers above 3 oz.

- Tight impedance control requirements

- Semi-additive processes

- Buried / blind vias

Minimize special processing needs through design when feasible.

Testing

Testing screening during manufacturing adds cost but critical for reliability:

- Netlist testing – Continuity and short circuit testing

- ICT (in-circuit test) – Validates board assembly

- Flying probe – Tests electrical parameters and boards

- AOI (automated optical inspection) – Optical inspection of solder, components, defects

- X-Ray inspection – Checks internal layers and BGA bonds

Higher test coverage requires additional equipment, programming, and cycle time.

Certifications

Special certifications like UL, military class, CE, RoHS, etc. often require additional documentation, testing, and ultimately cost. Avoid unnecessary certifications.

Onshore vs. Offshore

Location of the PCB supplier factors into cost:

- Onshore (USA, Europe) – Easier logistics and communication

- China – Very low cost, but long lead times

- Other Asia (Taiwan, Japan, S. Korea) – Balances cost and capabilities

Compare total cost including shipping, duty, and project risk factors.

Estimating Price Per Square Inch

As a rough starting point, use $100 per square inch of board area as an average for medium complexity, moderate volume rigid-flex PCBs. Adjust from there based on:

- Layer count

- Size impact

- Advanced materials

- Tight tolerances

- Special processing

This provides first pass estimate to assess if budget can absorb flex PCB expenses. Obtain quotes to dial-in accurate pricing.

Flex PCB Cost Reduction Tips

Here are ways to potentially reduce flex PCB costs through design optimization:

- Minimize layers and vias

- Standardize on common materials like polyimide

- Reduce stiffeners/shielding unless critical

- Avoid tiny components requiring laser cutting

- Relax tolerances as much as possible

- Standaradize on a single board thickness when possible

- Reuse PCB profiles across product generations

- Build a little extra board spacing to facilitate panelization

- Work with fab to optimize panel layouts and tooling

Conclusion

Estimating the costs for a flex PCB design requires balancing performance needs with manufacturing efficiency. As with rigid PCBs, flex circuit costs are highly dependent on size, layer count, materials, processing complexity, order quantities, and other factors explored here.

While inherently more expensive than rigid boards, flex PCBs enable unique mechanical packaging capabilities. By budgeting wisely and optimizing designs for manufacturability, engineers can cost-effectively utilize flex PCB technology where it provides the greatest benefit.

Frequently Asked Questions

Q: What are typical cost ranges per square inch of flex PCBs?

A: As a rough estimate, small prototype 2-layer boards may start around $100/in2, while complex 12+ layer flex in production could reach $500/in2 or more.

Q: What are ways to reduce layers in a flex PCB design to cut costs?

A: Carefully analyze trace routing to utilize both sides of boards. Leverage vias for routing between layers only when necessary. Plan layer stackup wisely.

Q: Should every flex PCB design use maximum thickness dielectrics?

A: Thinner dielectrics enable better flexibility and cost savings. Only use thicker material when essential for mechanical robustness and preventing tearing.

Q: How can stiffeners and shielding be minimized in flex circuits?

A: Analyze parts of the circuit that actually require enhanced rigidity. Spot-apply stiffeners only in those areas. Use shielding very strategically just where needed.

Q: Is automation design software worth the investment for flex PCBs?

A: The learning curve and seat costs are justified through facilitating rapid design iterations, DFM analysis, and optimizing to minimize layers/tolerances/materials.

Flex PCB Cost Estimator is very important for a designer who is developing a flex PCB , A good flex circuit engineer not only complete layout design , but also control the production cost for projects or for company , Every day , we get hundreds inquiries , some designs really waste money ,big size , as a flex PCB manufacturer , we do like big size , but as a project ,We still suggest you control size , layers to save cost .

How many aspect to do flex pcb cost estimator ?

1. Layers, Is the most important factor, if single side flex is enough , never try more layer

2. Flex Board types: Single Pieces or in Panel , when do Flex PCB Cost Estimator , we consider material utilization rate , flex PCB material is roll unit , one of side canot be more then 250mm , when production , we will set working panel size , if waste lots , this will calculate into flex pcb cost .

3. Min Track/Spacing 2-3mil .

4. Min Hole Size not be too small , 0.25

5. Gold Fingers two option for flex pcb gold finger, hard gold or immersion gold , hard gold is much more expensive .

6. Copper Thickness 1/3 oz is normal, keep flexible , not suggest heavy copper .

7. Stiffener, Flex PCB connector have 3 option to select stiffener : Fr4 stiffener , Aluminum stiffener , Pi stiffener , if you Plug frequency ,suggest use more harder stiffener .

8.Surface Finish normal is immersion gold

9. Size more material utilization rate, more cheaper

10. Quantity, The more the cheaper

Why donot RayMing use online flex PCB cost estimator ?

Flex pcb cost estimator isnot easy as rigid PCB cost estimator, Rigid PCB material size have lots of option , So we can choose different size material to do working panel Maximum possible utilization rate , But flex PCB material is roll size , one size must be less than 250mm . So we use online customer support to calculate exact price to avoid any mistake .

Ray PCB have rich experience in Flex PCB manufacturing and Cost Estimator , we deliver products on time and support low-volume and high volume production requirements to meet the different needs of our customers, contact us for a quote today!