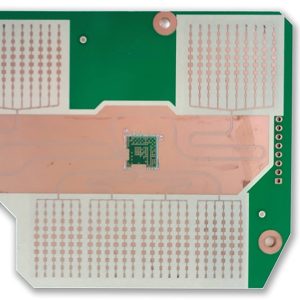

RO4835+FR4 Mixed Pressure High Frequency PCB

Board Material: Rogers RO4835+IT180A

Board thickness: Core thickness of 0.254mm, finished board thickness of 1.2mm

Layers: 8 layers PCB

Minimum line width / line spacing: 4/4mil

Finished copper thickness: inner layer 1OZ, outer layer 1OZ

Acceptance standard: IPC6012 CLASS 3 level

Surface Finished: Immersion Gold

Dielectric constant: 3.48+/-0.0

Advantage of RO4835+FR4 mixed-press high frequency board

RO4835+FR4 mixed-press high frequency board is a special high frequency circuit board, which is made of Rogers RO4835 and FR4 material mixed-press. This board has good high frequency performance and stable electrical characteristics and is suitable for high frequency communication, microwave circuits, radar systems and other fields.

Rogers RO4835 is a high-performance microwave circuit board material with extremely low dielectric constant and loss factor, which maintains excellent electrical properties at high frequencies, while FR4 is a common circuit board material with high mechanical strength and processability.

Through the RO4835 and FR4 mixed pressing, you can make full use of the advantages of the two materials, to obtain both excellent high-frequency performance and good mechanical strength of the circuit board. This mixed-pressing high-frequency board has an important application value in high-frequency circuit design, which can improve the stability and reliability of the circuit and reduce the loss and distortion of signal transmission.

The advantages of RO4835+FR4 hybrid high-frequency boards mainly include the following aspects:

Excellent high-frequency performance: RO4835 material has a very low dielectric constant and loss factor, which makes the mixed-pressure high-frequency board maintain excellent electrical performance at high frequencies, and is suitable for high-frequency communications, microwave circuits and other fields.

High mechanical strength: FR4 material has high mechanical strength, so that the mixed pressure high frequency board has good mechanical stress resistance performance, suitable for applications that need to withstand greater mechanical stress.

Good processing performance: FR4 material has good processing performance, which makes the mixed-pressure high-frequency board easy to process and manufacture, and improve the production efficiency.

Strong antioxidant performance: RO4835 material has excellent antioxidant performance, so that the mixed-pressure high-frequency board in the long-term use process can maintain stable electrical properties, prolonging the service life.

RO4835+FR4 mixed-press high-frequency boards have excellent high-frequency performance, high mechanical strength, good processing performance and strong antioxidant properties, suitable for a variety of applications that require high-frequency circuit boards.

The application areas of RO4835+FR4 mixed-compression high-frequency boards mainly include the following:

Communication field: RO4835+FR4 mixed-compression high-frequency boards have excellent high-frequency performance and are suitable for high-frequency circuit design in a variety of communication equipment, such as cell phones, base stations, routers and so on.

Radar system: radar system needs to deal with a large number of high-frequency signals, RO4835+FR4 mixed-voltage high-frequency board with high-frequency performance and stability can meet the requirements of the radar system.

Electronic equipment: high frequency circuit design in electronic equipment requires the use of high frequency circuit boards, RO4835+FR4 mixed voltage high frequency boards can meet the requirements of these devices.